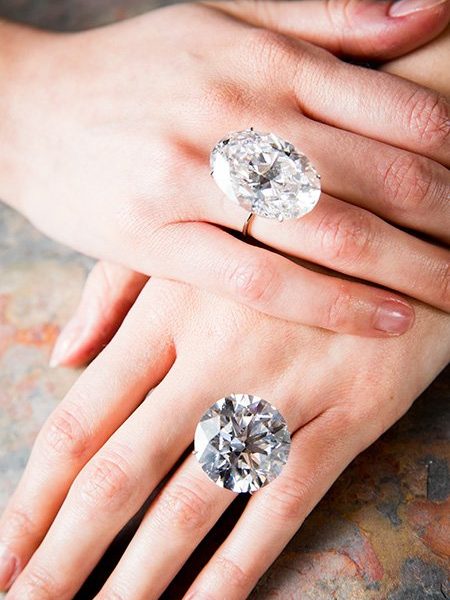

Ever wondered how a diamond cutter works, unlocking the inner beauty and “fire” of these extraordinarily precious gems? From rough to polished stone.Perhaps not often associated with the art of sculpting, diamond cutters are highly skilled sculptors in their own right. Through years of experience, a scholarly understanding of geology, patience and concentrated precision, these artisans have hatched the most dazzling gems in existence. In 1375 the first guild of diamond cutters and polishers was established in Nuremberg, Germany. Called the Diamantaire, the guild developed various types of “cuts”: the shape and the quality of cut within the diamond. The first major development in diamond cutting came in the latter half of the 14th century with the creation of the “Point Cut”. This cut follows the natural shape of an octahedral rough diamond crystal, eliminating waste during the cutting process. This art has evolved greatly over the past several hundred years. With the use of advanced technology, diamonds cut today are an art of precision. There are several factors that must be analysed during the planning stages of cutting. A foremost consideration is how to cut the stone to maximise its value. Both the popularity of certain shapes among consumers as well as physical factors such as the shape of the rough stone, location of inclusions and flaws determine shape.

Through years of experience, a scholarly understanding of geology, patience and concentrated precision, these artisans have hatched the most dazzling gems in existence. In 1375 the first guild of diamond cutters and polishers was established in Nuremberg, Germany. Called the Diamantaire, the guild developed various types of “cuts”: the shape and the quality of cut within the diamond. The first major development in diamond cutting came in the latter half of the 14th century with the creation of the “Point Cut”. This cut follows the natural shape of an octahedral rough diamond crystal, eliminating waste during the cutting process. This art has evolved greatly over the past several hundred years. With the use of advanced technology, diamonds cut today are an art of precision. There are several factors that must be analysed during the planning stages of cutting. A foremost consideration is how to cut the stone to maximise its value. Both the popularity of certain shapes among consumers as well as physical factors such as the shape of the rough stone, location of inclusions and flaws determine shape. Scanning devices and 3-dimensional models are used to find an optimal way to cut the stone.Typically, round and square brilliant cuts are preferred when the crystal is an octahedron, as often two stones may be cut from one crystal. Oddly shaped crystals, such as macles are more likely to be cut in as a fancy cut. Secondly, weight retention analysis must be assessed to find the best combination of the finished stone and how it relates to per carat value. Even with modern techniques, cutting and polishing a diamond always results in dramatic weight loss, about 50%. Finally, colour retention is studied in the rough as it will influence the colour grade of the diamond, either increasing or decreasing its value.Once the diamond is assessed and the cutter commits to a blueprint, the first step is to cleave or saw the rough into separate pieces to be completed as separate gems. Bruting is the process where a diamond cuts a diamond; two diamonds are set onto spinning axels turning in opposite directions, which are set to grind against each other to shape each diamond into its intended shape.

Scanning devices and 3-dimensional models are used to find an optimal way to cut the stone.Typically, round and square brilliant cuts are preferred when the crystal is an octahedron, as often two stones may be cut from one crystal. Oddly shaped crystals, such as macles are more likely to be cut in as a fancy cut. Secondly, weight retention analysis must be assessed to find the best combination of the finished stone and how it relates to per carat value. Even with modern techniques, cutting and polishing a diamond always results in dramatic weight loss, about 50%. Finally, colour retention is studied in the rough as it will influence the colour grade of the diamond, either increasing or decreasing its value.Once the diamond is assessed and the cutter commits to a blueprint, the first step is to cleave or saw the rough into separate pieces to be completed as separate gems. Bruting is the process where a diamond cuts a diamond; two diamonds are set onto spinning axels turning in opposite directions, which are set to grind against each other to shape each diamond into its intended shape.  Once the diamond begins taking shape, the cutter then polishes the diamond, cutting facets onto the diamond whereby unlocking its inner brilliance. Finally, the diamond is cleaned using acids, followed by a thorough examination process to grade its cut, colour, clarity and carat weight. Today, diamond cutting is concentrated in a few cities around the world. From diamond trading centers such as Antwerp and Tel Aviv to processing centers and finally to places like New York City where a majority of the most important diamonds in the world are cut, these cities hold the artisans that unlock a diamond’s inner beauty; a beauty that has inspired emotion for thousands of years.

Once the diamond begins taking shape, the cutter then polishes the diamond, cutting facets onto the diamond whereby unlocking its inner brilliance. Finally, the diamond is cleaned using acids, followed by a thorough examination process to grade its cut, colour, clarity and carat weight. Today, diamond cutting is concentrated in a few cities around the world. From diamond trading centers such as Antwerp and Tel Aviv to processing centers and finally to places like New York City where a majority of the most important diamonds in the world are cut, these cities hold the artisans that unlock a diamond’s inner beauty; a beauty that has inspired emotion for thousands of years.

#Diamond #Popley #Popleydiamonds

Shop for deals online at https://www.garnerbears.com